2. Method of formation

The bubbles are blown from a fine orifice, beneath the surface of a soap solution. We have had the best results with a solution the formula of which was given to us by Mr. Green of the Royal Institution. 15-2 c.c. of oleic acid (pure redistilled) is well shaken in 50 c.c. of distilled water. This is mixed thoroughly with 73c.с. of 10% solution of tri-ethanolamine and the mixture made up to 200 c.c. To this is added 164 c.c. of pure glycerine. It is left to stand and the clear liquid is drawn off from below. In some experiments this was diluted in three times its volume of water to reduce viscosity. The orifice of the jet is about 5 mm. below the surface. A constant air pressure of 50 to 200cm. of water is supplied by means of two Winchester flasks. Normally the bubbles are remarkably uniform in size. Occasionally they issue in an irregular manner, but this can be corrected by a change of jet or of pressure. Unwanted bubbles can easily be destroyed by playing a small flame over the surface. Figure 1 shows the apparatus. We have found it of advantage to blacken the bottom of the vessel, because details of structure, such as grain boundaries and dislocations, then show up more clearly.

Figure 2, plate 8, shows a portion of a ' raft' or two-dimensional crystal of bubbles. Its regularity can be judged by looking at the figure in a glancing direction. The size of the bubbles varies with the aperture, but does not appear to vary to any marked degree with the pressure or the depth of the orifice beneath the surface. The main effect of increasing the pressure is to increase the rate of issue of the bubbles. As an example, a thick-walled jet of 49? bore with a pressure of 100cm. produced bubbles of 1-2 mm. in diameter A thin-walled jet of 27? diameter and a pressure of 180cm. produced bubbles of 0.6 mm diameter It is convenient to refer to bubbles of 2.0 to 1.0mm. diameter as 'large' bubbles, those from 0.8 to 0.6mm. diameter as 'medium' bubbles, and those from 0.3 to 0.1 mm. diameter as 'small' bubbles, since their behaviour varies with their size.

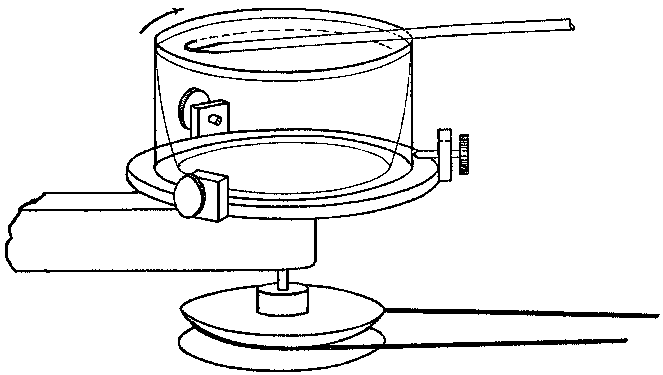

figure 3. Apparatus for producing bubbles of small size.

With this apparatus we have not found it possible to reduce the size of the jet and so produce bubbles of smaller diameter than 0.6 mm. As it was desired to experiment with very small bubbles, we had recourse to placing the soap solution in a rotating vessel and introducing a fine jet as nearly as possible parallel to a stream line. The bubbles are swept away as they form, and under steady conditions are reasonably uniform. They issue at a rate of one thousand or more per second, giving a high-pitched note. The soap solution mounts up in a steep wall around the perimeter of the vessel while it is rotating, but carries back most of the bubbles with it when rotation ceases. With this device, illustrated in figure 3, bubbles down to 0.12 mm. in diameter can be obtained. As an example, an orifice 38? across in a thin-walled jet, with a pressure of 190cm. of water, and a speed of the fluid of I80cm./sec. past the orifice, produced bubbles of 0.14 mm. diameter. In this case a dish of diameter 9-5 cm. and speed of 6 rev./sec. was used. Figure 4, plate 8, is an enlarged picture of these 'small' bubbles and shows their degree of regularity; the pattern is not as perfect with a rotating as with a stationary vessel, the rows being seen to be slightly irregular when viewed in a glancing direction.

These two-dimensional crystals show structures which have been supposed to exist in metals, and simulate effects which have been observed, such as grain boundaries, dislocations and other types of fault, slip, recrystallization, annealing, and strains due to ' foreign' atoms.

Более 800 000 книг и аудиокниг! 📚

Получи 2 месяца Литрес Подписки в подарок и наслаждайся неограниченным чтением

ПОЛУЧИТЬ ПОДАРОК